How to replace fuel line on your portable generator

- BY BISON

Table of Contents

A portable generator’s fuel line plays a vital role in moving fuel from the tank to the engine, ensuring smooth operation and continuous power output. As one of the most critical components in a portable generator’s fuel system, a properly functioning fuel line is essential for optimal performance. However, wear, heat, or accidental damage can cause a fuel line to rupture or leak, which can affect the efficient operation of a portable generator.

Maintaining the fuel line and promptly addressing issues are key to preventing larger problems, such as engine failure or unsafe conditions caused by a fuel leak. Neglecting a ruptured fuel line can affect the reliability and safety of a portable generator, leaving you without power at a critical moment.

In this article, BISON will provide you with step-by-step instructions for safely replacing a ruptured fuel line on a portable generator. Read on to learn how to restore your unit to peak condition!

Symptoms of a ruptured fuel line

One of the most obvious signs of a ruptured fuel line on a portable generator is a generator fuel leak, which usually manifests as wet spots, puddles, or a gasoline smell around the fuel line or tank. Another symptom is the engine stalling or making a puffing noise, which is caused by a lack of fuel supply interrupting normal operation. You may also notice that the portable generator has trouble starting because the engine is having trouble getting the fuel it needs to ignite.

Diagnosing a gasoline fuel leak

Proper fuel leak diagnosis requires careful inspection and strict adherence to safety procedures to prevent personal injury or fire hazards. Follow these steps to safely inspect the portable generator and determine the problem.

- Take safety precautions: Before beginning any inspections, make sure the portable generator is off and allow the engine to cool completely. Disconnect the portable generator from any power source or electrical load. Operate in a well-ventilated area, away from open flames, sparks, or any possible ignition sources. Gasoline fumes are extremely flammable. Consider wearing gloves and safety glasses to avoid contact with fuel or fumes.

- Inspect the fuel lines: Carefully check fuel lines for any signs of tears, cracks, or wear. Pay close attention to areas near elbows or connections, as these areas are more susceptible to damage over time. If leaks or deterioration are found, the fuel line may be the source of the problem and needs to be replaced.

- Inspect the carburetor: The carburetor is another component that can leak due to damaged hoses, clogged passages, or loose connections. Check for signs of fuel dripping or accumulation around the carburetor, as this could indicate other problems with the fuel line or other connected parts.

- Check the fuel tank and stopcock: Finally, examine the fuel tank for cracks or holes that could cause leakage. Check the stopcock (fuel valve) for any signs of wear or damage, as its failure could cause uncontrolled fuel flow. Make sure all connections to the fuel line are secure and free of corrosion.

Following these steps, you can pinpoint the source of the problem. Once you identify the problem as a damaged fuel line, you can move forward with replacing it.

How to replace a gasoline fuel line on a portable generator

Tools and materials required

- Tools: Screwdriver, pliers, utility knife, or scissors.

- Materials: Replacement fuel line, fuel-resistant cleaner, hose clamp, protective gloves.

Fuel line replacement steps

Step 1: Locate the fuel line

Before you begin, locate the fuel line that runs from the tank to the carburetor. Refer to the portable generator’s owner’s manual for its exact location, as its location may vary by brand and model.

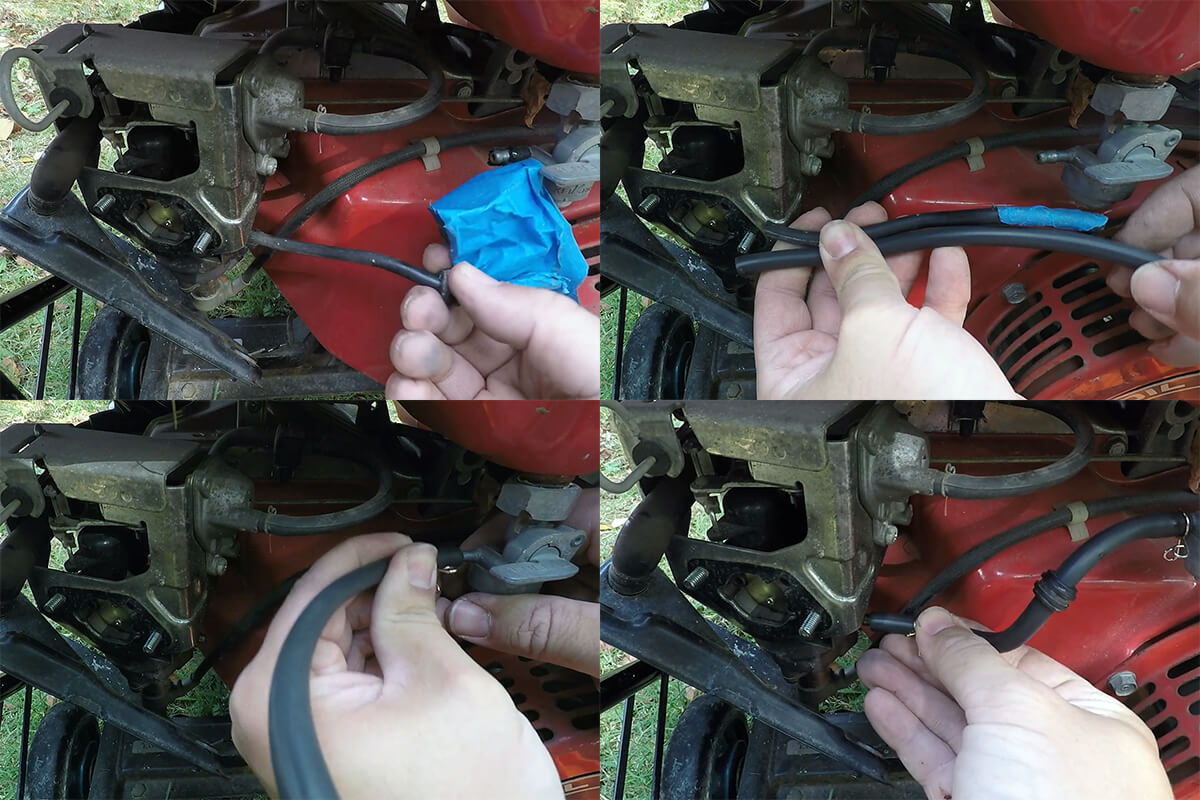

Step 2: Unplug the fuel line

1. Disconnect the hose clamp

Use either a pliers or a screwdriver to gently loosen the hose clamp that fixes the fuel line.

If the hose clamp is too tight or rusted:

Apply a small amount of penetrating oil to the hose clamp screw and let it sit for a few minutes.

Lightly tap the hose clamp with a screwdriver handle or pliers to remove stubborn corrosion.

Avoid excessive force to avoid damaging the connector.

2. Remove the damaged fuel line

After the hose clamp is loosened, carefully pull the fuel line out of the fittings on both the fuel tank and carburetor.

If the old fuel line is stuck, use pliers to gently grip and twist it to loosen it from the fitting.

When removing the line, be careful not to damage nearby components or fittings.

Dispose of the old fuel line properly, as it may contain traces of gasoline.

Step 3: Install the new fuel line

Cut the replacement fuel line: Measure the length of the new fuel line against the old fuel line and trim it to the appropriate length using a utility knife or scissors. Avoid leaving excess slack to prevent the line from kinking.

Connect the new fuel line:

- Slide one end of the new fuel line securely onto the fitting on the fuel tank.

- Secure this connection with a hose clamp and tighten it with a screwdriver until it is snug but not over-tightened.

- Repeat the process for the other end of the fuel line, connecting it to the carburetor and securing it with another hose clamp.

Tips for a proper installation

Make sure the fuel line has a smooth, natural curve with no kinks, bends, or twists.

Before clamping, double-check that both ends are fully secured to their respective fittings.

Step 4: Check the connection

Once the new fuel line is installed:

Check the clamp to make sure it is securely fastened. Tighten if necessary, but do not over-tighten as this may damage the line or fitting.

Clean any gasoline residue from the connection with a fuel-resistant cleaner and allow the area to dry before proceeding.

Test for leaks:

Reconnect the fuel line to the stopcock or fuel valve and turn it on. Carefully inspect the area around the connection to see if there are any indications of fuel leakage. If you find any leaks, adjust the clamp until the connection is secure.

Summary

By following the steps above and observing proper safety precautions, you can effectively replace a damaged gasoline fuel line and extend the life of your portable generator. Regular maintenance and inspection of components, including fuel lines, is key to ensuring the portable generator is reliable and safe.

However, if you are unsure of your ability to make repairs or encounter any challenges, it is always wise to consult a professional technician to help you avoid damaging the portable generator.

As a trusted supplier of portable generators, BISON offers durable, high-performance portable generators. By doing business with BISON, you won’t have to worry about frequent machine failures or having to worry about replacing fuel lines. BISON’s high-quality generators require minimal maintenance, and our experienced experts provide timely after-sales assistance to our dealers.

contact us

related product categories

Get in touch to speak with our experts!