How to bypass low oil sensor on generator

- BY BISON

Table of Contents

A low oil sensor is a critical safety feature in a generator, designed to protect the engine from serious damage. It prevents the engine from running without proper lubrication, which can cause overheating, severe internal wear, reduced efficiency, expensive repairs, or even complete engine failure.

These sensors continuously monitor oil levels and automatically shut down the generator when levels fall below safe thresholds. This helps avoid costly breakdowns, bearing damage, and irreversible mechanical failure.

Despite their protective function, low oil sensors can sometimes interfere with operation. Common issues include sensor malfunctions, false alarms from vibration or sensor drift, temporary emergency situations requiring power, or aging sensors that become overly sensitive.

This guide provides steps on how to safely bypass a low oil sensor, diagnostic methods to identify a sensor fault, and troubleshooting tips. We also explain how the sensor works, why problems may occur, and how to address them safely.

Important tips from BISON:

Bypassing a low oil sensor should only be a temporary emergency measure, not a permanent solution. It removes a critical safety feature and requires constant manual monitoring of oil levels. Before any bypass, always check oil levels using the dipstick and ensure enough oil for your intended operation.

Understanding the low oil sensor and how it protects your engine

A low oil sensor is a small but essential safety device in an engine. Its primary function is to monitor oil levels and alert you if they fall below a safe threshold, preventing serious engine damage from insufficient lubrication and reducing the risk of overheating and fire hazards.

The sensor typically uses a float or an electrical switch inside the oil reservoir. When oil levels are normal, the circuit signals that it’s safe to run. If the oil drops too low, the circuit triggers a warning light, buzzer, or, in some models, automatically shuts down the engine.

Low oil sensor warnings can be caused by genuine low oil levels due to leaks or neglect, but they can also result from faulty wiring, dirt or sludge on the sensor, or a worn-out switch. It’s important to check the actual oil level before assuming the sensor itself is malfunctioning.

Basic safety steps before working on a generator

Safety is the top priority before performing any generator maintenance. First, turn off the generator completely and allow it to cool. Generators can become extremely hot, and touching hot parts can cause serious burns.

Keep the work area clear of open flames or flammable materials. Fuel vapors and residual oil can ignite easily, so always work in a well-ventilated, safe environment.

Always consult the generator’s owner’s manual before starting maintenance. It provides model-specific safety instructions, step-by-step guidance, and precautions to prevent accidents or damage. Remember, bypassing a low oil sensor should only be considered if it is triggering unnecessarily.

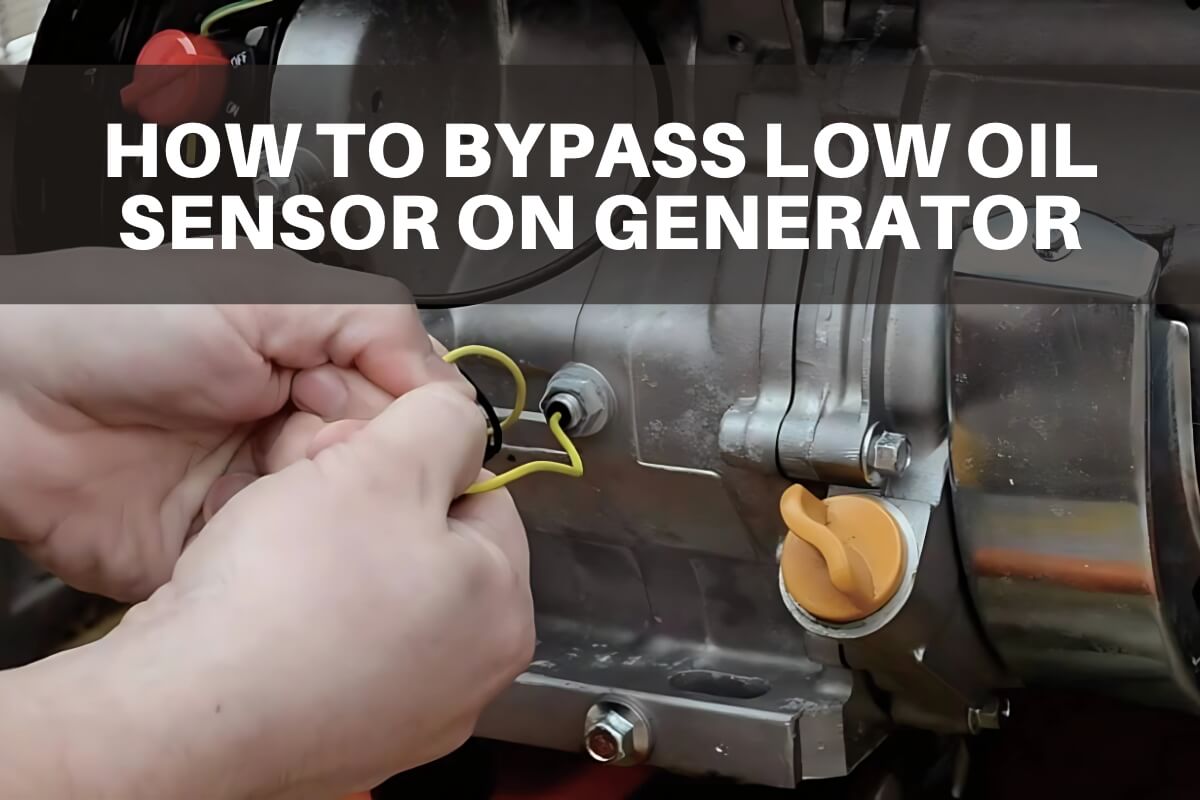

How to bypass the low oil sensor on a generator

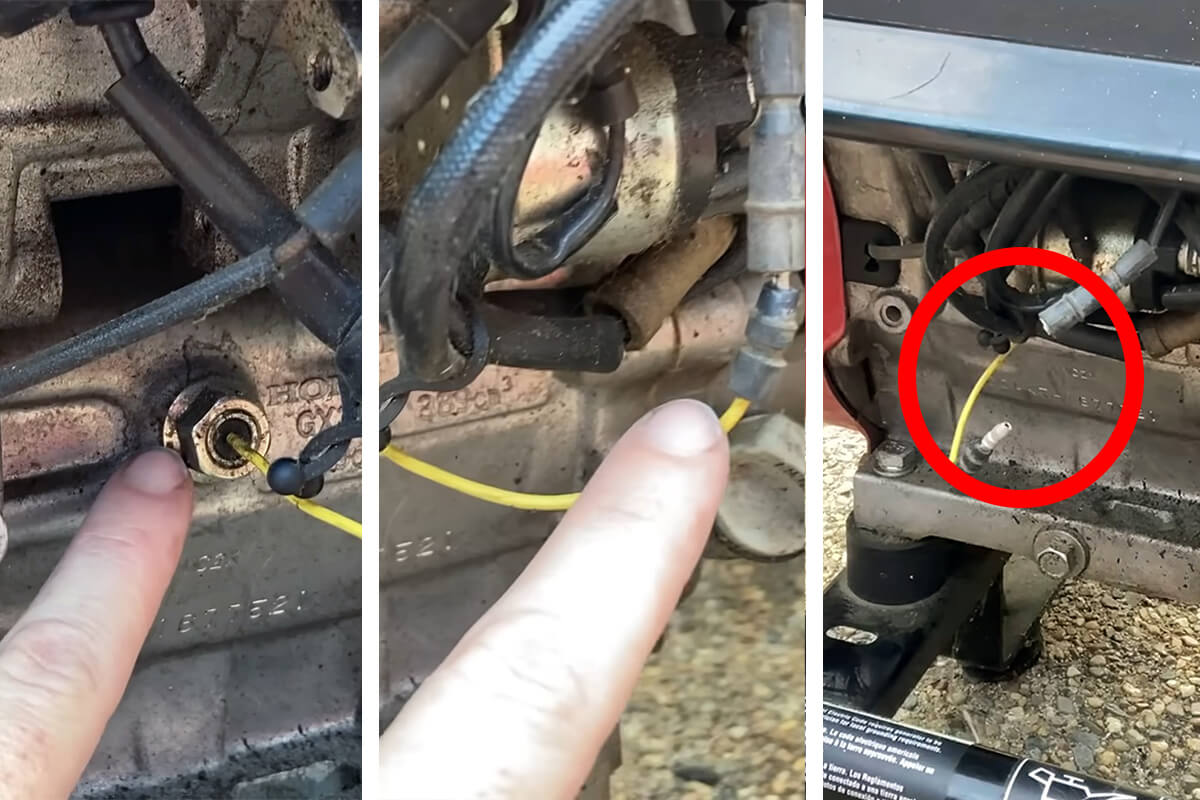

1. Disconnect the sensor wire

Locate the low oil sensor, usually near the crankcase under the panel and close to the oil fill cap. Carefully unplug the sensor wire and insulate it with electrical tape or a wire cap to prevent accidental short circuits.

2. Use the grounding method (for some models)

Some generators allow sensor bypass by grounding the sensor terminal. If your model supports this, connect the sensor terminal temporarily to a safe ground point to simulate normal oil levels.

3. Use a jumper wire

For switch-style sensors, a short jumper wire can connect the sensor terminals, closing the circuit and tricking the generator into detecting normal oil levels. Ensure the wire is secure and insulated from other components.

Note: After bypassing the sensor, carefully start the generator and monitor closely to perform a generator test. Listen for unusual sounds, watch for smoke, and check engine temperature. Stop immediately if anything appears abnormal.

Dangers of bypassing a generator’s low oil sensor

- Safety concerns: Generators burn fuel to produce electrical power. Without a low-oil sensor, overheating or ignition of flammable materials becomes more likely, creating fire hazards. Ignoring safety features can also compromise the generator’s electrical integrity, potentially causing malfunctions that endanger connected equipment, electrical systems, and bystanders.

- Warranty implications: Manufacturers install low oil sensors to ensure safe, reliable operation. Bypassing the sensor may void the warranty, leaving you responsible for repair costs or damage caused by the modification.

- Legal and liability considerations: Some regions have legal or regulatory requirements for safe generator operation. Ignoring safety features can result in non-compliance, and any damage or loss caused by bypassing the sensor may create legal liability for the operator.

In summary, bypassing the low oil sensor should only be done temporarily for emergencies or troubleshooting. Normal oil monitoring must always be restored to maintain safe and reliable generator operation.

A safer alternative to bypassing the low oil sensor

The safest way to avoid low oil sensor problems is to regularly check your generator’s oil level and perform timely oil changes according to the manufacturer’s recommendations. Proper oil maintenance ensures the sensor functions correctly and protects the engine from damage.

In addition to oil care, follow other routine maintenance tasks outlined in the owner’s manual. This includes cleaning or replacing air filters, inspecting fuel lines for leaks or cracks, and checking spark plugs for wear.

By keeping up with these simple maintenance steps, you can prevent sensor issues, maintain reliable generator operation, and extend the engine’s lifespan.

Troubleshooting common low oil sensor problems

If your generator’s low oil sensor keeps triggering, inspect the system carefully to identify the cause.

- Defective gauge: Sometimes the sensor triggers due to a faulty oil pressure gauge. Verify oil levels manually. If levels are normal but the sensor still activates, the gauge may be malfunctioning. In this case, replacing the sensor or gauge can resolve the issue.

- Wiring issues: Inspect the wiring connecting the sensor to the control panel. Look for loose, frayed, or damaged wires that could interrupt the signal. Ensure all connectors are secure and free from corrosion.

- Control panel problems: A malfunctioning control panel can also cause false alerts or prevent the sensor from working properly. If the sensor and wiring are fine but issues persist, the control panel may require professional inspection.

- Clogged filter: A clogged filter can lead to oil starvation, preventing the bypass valve from working correctly. Regular filter maintenance is essential to avoid oil problems and protect the generator.

- Normal wear and tear: Frequent sensor activation can also indicate the generator is aging or heavily used. Consider the generator’s age and usage; it may be nearing the end of its service life.

Summary

Bypassing a generator’s low oil sensor should only be a temporary measure, used in emergencies or for troubleshooting. Even when the sensor is bypassed, always monitor oil levels carefully to prevent engine damage. For long-term safety and reliable performance, repair or replace any faulty sensor as soon as possible.

To keep your generator in top condition, choose high-quality generators and replacement parts from BISON. As a trusted generator supplier in China, BISON provides industry-leading products, professional manufacturing, and reliable support, allowing dealers to confidently start business cooperation. By choosing to start a business partnership with BISON, you can ensure your engines remain safe, efficient, and durable while offering trusted solutions to your customers.

FAQs

How often should I check the oil level in my generator?

Check the oil level regularly according to the manufacturer’s instructions. As a general rule, inspect the oil before each use and perform oil changes as recommended in the owner’s manual.

What happens if the oil pressure sensor is unplugged?

If the oil pressure sensor is disconnected, the generator may display a warning light or message indicating low oil pressure or a sensor issue. Some models may also emit an audible alarm to alert the operator.

contact us

related product categories

Get in touch to speak with our experts!