water cooled generators manufacturers & suppliers

BISON professional water cooled generators deliver 24/7 reliable power with advanced cooling technology. Select your ideal model for continuous operation.

power life from here

power life from here

why choose

BISON water cooled generator

why choose

BISON water cooled generator

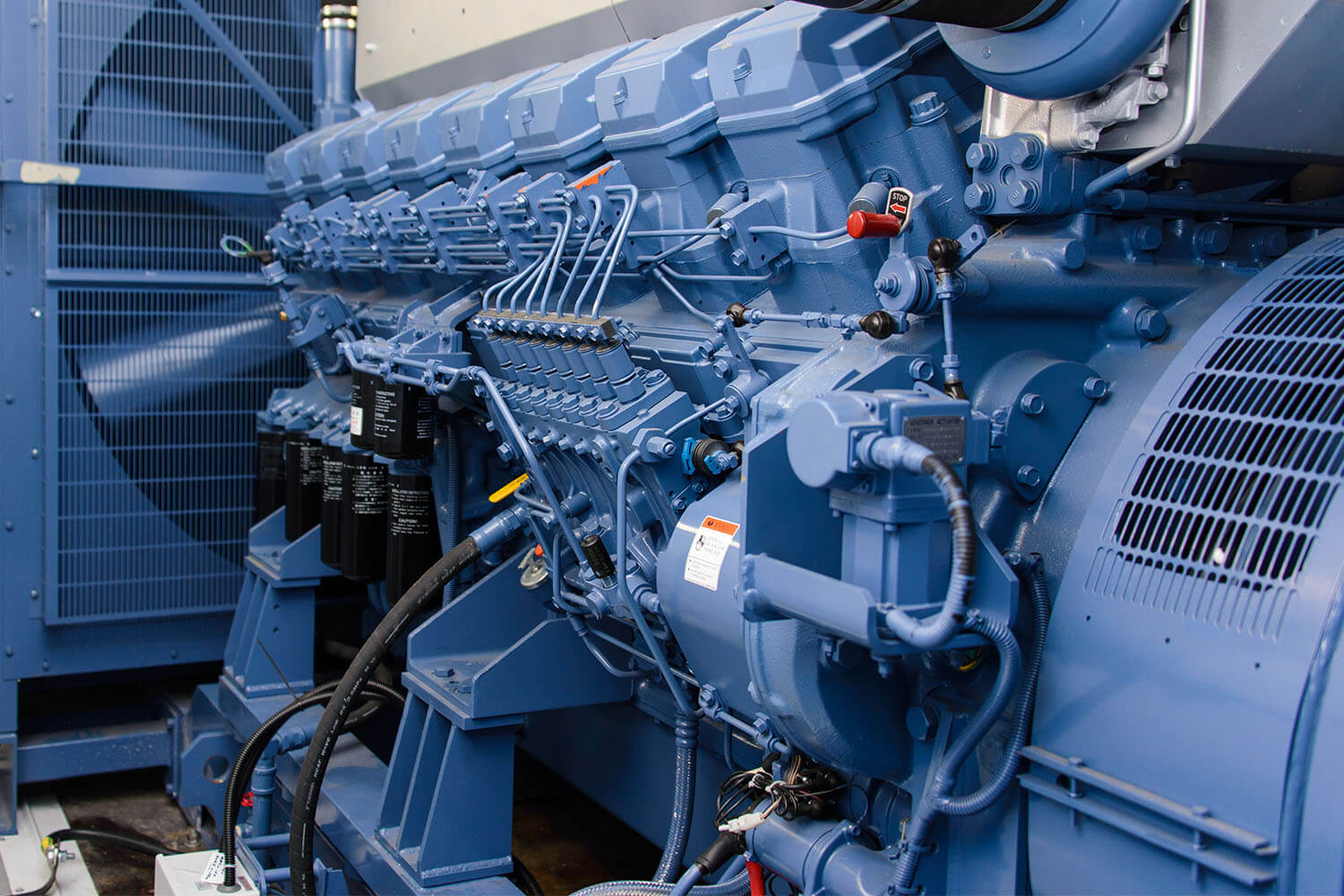

advanced cooling system

High precision thermal control: Revolutionizes cooling efficiency through innovative engineering design.

Strictly selected materials and workmanship: always reliable and error-free under harsh conditions.

Continuous power guarantee: long-term power endurance to meet large-scale industrial needs.

cash show

case show

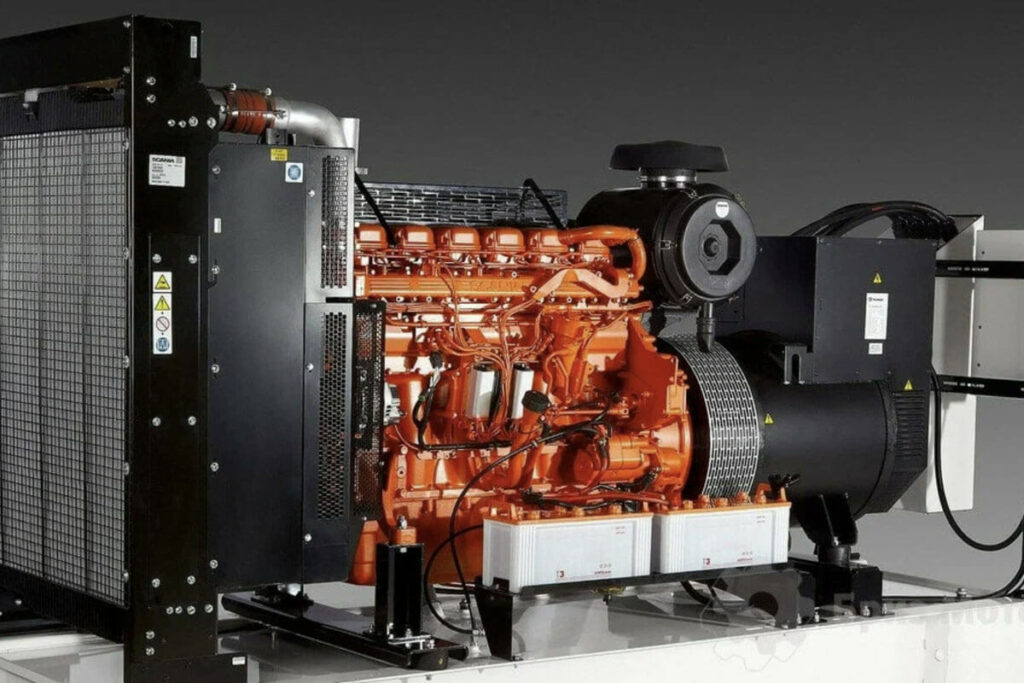

empowering zimbabwe: YUCHAI-powered gensets fuel mining success

Our Diesel Gensets, powered by YUCHAI engines, have played a pivotal role in Zimbabwe’s mining industry. We provided two 1250kVA generator sets, offering stable and reliable power support in challenging working environments. These gensets have ensured the continuity of mining operations, making significant contributions to the local economic development.

PERKINS gensets powering factory operations in turkey

Our Diesel Gensets, powered by YUCHAI engines, have played a pivotal role in Zimbabwe’s mining industry. We provided two 1250kVA generator sets, offering stable and reliable power support in challenging working environments. These gensets have ensured the continuity of mining operations, making significant contributions to the local economic development.

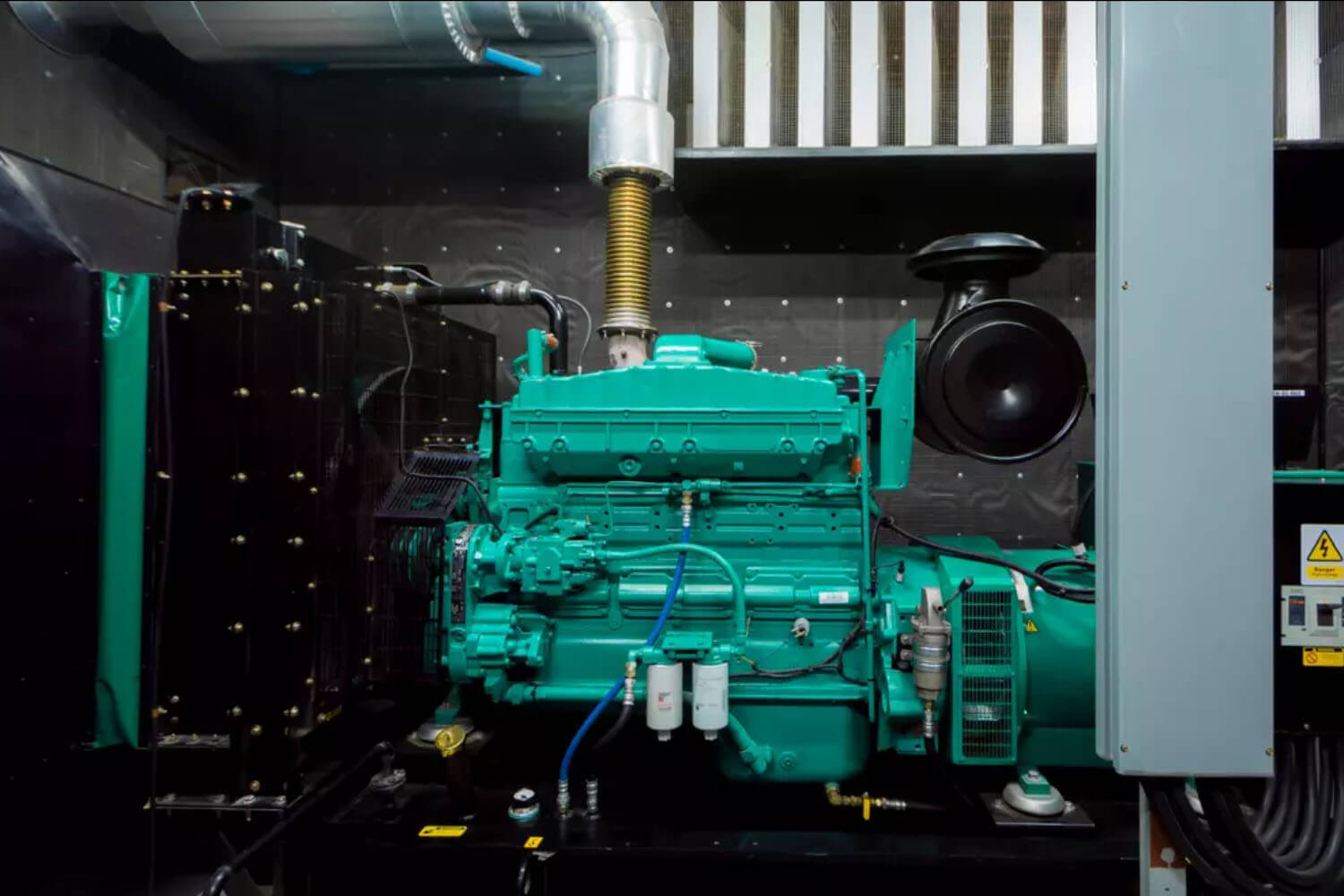

enhancing quarry operations: 200kw CUMMINS silent gensets

Step into the world of quarry operations in Spain, where the quiet power of two 200kW CUMMINS gensets drives efficiency. These silent but powerful machines provide essential electricity to support operations in the quarry. Watch now to see how our gensets are revolutionizing the Spanish quarry industry!

testing of a 200kw CUMMINS silent genset for a quarry in russia

A 200kW CUMMINS Silent genset, destined for a quarry in Russia, is currently undergoing on-site testing in China. This silent generator set is being rigorously tested to ensure its reliability and performance in harsh environments. Watch the on-site testing to learn how we deliver high-quality power solutions to global customers!

quarry operations: YUCHAI genset powers crushing production line

Experience the efficiency of a Chinese quarry, where a single 300kW YUCHAI silent genset drives the crushing production line. With its silent operation, this genset ensures smooth and uninterrupted power supply to support the quarry’s operations. Watch now to see how our gensets are enhancing productivity in the Chinese quarry industry!

frequently asked questions

frequently asked questions

Can a water cooled generator be used in all environments?

While water-cooled generators can operate in most environments, there are some limitations, such as cold climates, limited water sources, or cooling systems. In these cases, an air-cooled generator may be a better choice.

Can I convert an air-cooled generator to a water-cooled one?

systems are designed differently, and replacing them requires major modifications, including manufacturing a custom water jacket, designing new cooling channels, and installing a complete cooling system (including radiators, water pumps, and piping). BISON’s engineers have seen DIY attempts end in coolant showers and fried windings. Truth is – by the time you hack it together, you’ve spent more than just buying proper water-cooled gear.

What happens if the water cooling system fails?

If the coolant system stops doing its job, you’re looking at a generator that’s basically running a fever. Metal parts may warp, seals may melt, and you may hear an angry knocking noise from the engine—a sign that things are going to get bad soon. To prevent such failures, the cooling system must be regularly inspected and maintained.

How to use a water-cooled generator safely?

- Read the manual: Always refer to the manufacturer’s instructions for proper operation and maintenance procedures. Each generator model may have specific requirements.

- Safe placement: The generator should be placed on a level, non-flammable, and slightly elevated surface away from flammable materials.

- Routine inspection: Check all hoses, clamps, and connections for signs of wear or damage.

- Electrical safety: Check electrical connections and wiring for damaged insulation. Before performing any inspection or maintenance, shut down the generator and disconnect it from the power source.

- Regular maintenance: Always follow the manufacturer’s operating and maintenance guidelines ensure that the operator is properly trained in emergency shutdown procedures and keep detailed logs after maintenance.

water cooled generator guide

water cooled generator guide

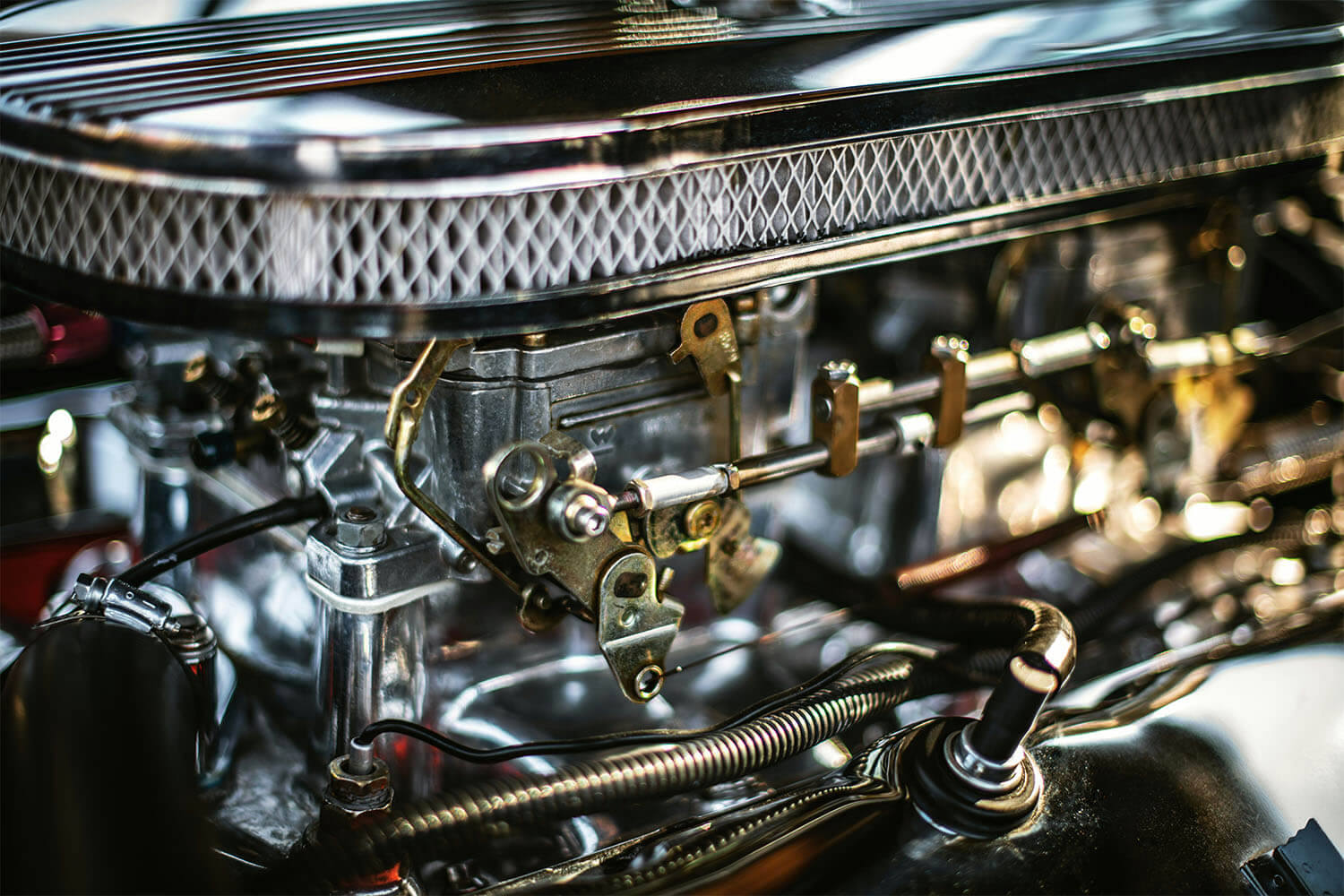

A water cooled generator is an advanced power generation system that circulates a liquid coolant to maintain optimal operating temperatures. Think of it like your car’s engine – instead of relying on basic air circulation, these systems use water-based cooling methods where specially formulated fluid moves through critical areas to carry away heat. This smart heat management approach helps the equipment work harder for longer without overheating.

The importance of the cooling system in generator operation cannot be overstated, as it is the cornerstone of reliable power generation. Without effective cooling, the high heat generated during operation can quickly lead to component degradation, reduced efficiency, and even system failure. With quiet operation, environmentally friendly features, and low maintenance costs, the BISON water cooled generator is a reliable choice for both large-scale operations and more localized power needs.

This article aims to provide a comprehensive introduction to the application of water-cooled power generation systems and their components in various industries.

Basic knowledge of water cooled generators

Water cooled generators employ a closed-loop thermal regulation system utilizing a water-based coolant (typically blended with antifreeze additives) to manage heat dissipation. The coolant circulates through precision-engineered channels within the generator assembly, absorbing thermal energy from critical components. This heated fluid then transfers through a dedicated heat exchanger, where forced-air convection and radiative cooling reduce its temperature. After heat dissipation, the coolant recirculates via pump-driven flow, maintaining consistent operational temperatures across load variations.

Cooling system components

The cooling system is a critical component in the operation of the generator, providing basic temperature control and a defense against large amounts of heat.

- Water pump: The heart of the cooling system. Usually driven directly by the engine, it forces the coolant to circulate, maintaining a consistent coolant flow

- Radiator/reservoir: Stores excess coolant and provides expansion space for heated coolant.

- Radiator: This is a key heat exchange component. It has multiple fins that work with multiple coolant flow channels to maximize heat dissipation.

- Water jacket: A channel built into the engine block that surrounds the cylinders and combustion chambers.

- Thermostat: Responds to temperature changes by regulating the flow of coolant through different circuits, and can automatically switch on and off at a predetermined temperature.

Advantages of water cooled generators

Efficient heat dissipation

Liquid coolants have a greater ability to transfer heat and cool more efficiently. About 30 times more than ordinary air cooling. They can maintain a stable optimal operating temperature even under heavy loads, which is particularly important for large-capacity generators and continuous operation applications. Its cooling effect is evenly distributed throughout the system, so it can easily dissipate heat even under high-temperature conditions.

Stable operating temperature

Advanced constant temperature control systems have a faster response to temperature changes and better overheating protection. Consistent temperatures can improve the overall performance of water cooled generators and reduce thermal stress on components.

Lower noise

Water-cooled generators are much quieter than air-cooled generators. Usually, our artificial noise level depends on the size and design of the generator, but in most cases, water-cooled generators produce less noise. This is because the presence of the cooling system eliminates large high-speed cooling fans and some moving parts, and the closed design and better insulation of the water cooling system naturally suppress operating noise.

Longer equipment life

Well-maintained water-cooled generators can have a service life of 15 to 30 years. By maintaining a constant operating temperature and reducing thermal stress, these systems minimize wear on seals, gaskets, and other important parts. BISON recommends that you regularly maintain and keep the cooling system in top condition to obtain long-term reliability and durability of the water cooled generator.

Higher power output capability

Efficient cooling enables the generator to run at maximum power for a long time. The lack of risk of overheating also means that these generators can be designed with a higher power density, providing more power in a relatively compact space.

Adaptable to different environments

The closed housing and closed cooling system are able to withstand the harsh conditions of the outside world. The performance of the water cooled generator will not drop significantly even in high-temperature environments or at high altitudes with low air density. Even if the external environment is dusty and dirty, the performance remains consistent.

How to choose the right water cooled generator

BISON water cooled generators are used for larger power requirements, with power options ranging from 20 kva to 300 kva.

- Power demand assessment: The most important step to find the right size for your needs is to conduct a comprehensive power assessment. This includes the running power and starting power of all power supply equipment. You should not only consider current needs but also consider future unexpected loads or growth, usually adding a 20-25% capacity buffer.

- Cooling system: As the core of the water cooled generator. Water quality specifications, flow requirements, temperature control needs, and pressure specifications must all be carefully considered. The cooling system should include heat exchangers, pumps, and control systems suitable for your specific application. In addition, consider whether a backup cooling system or redundancy measures are required to ensure continuous operation during maintenance or emergencies.

- Space requirements: The installation location needs to be equipped with sufficient water supply infrastructure and provide suitable drainage solutions. If you need to move the generator frequently, you can consider its portable model. BISON offers a variety of water cooled generators with mobility features, such as wheels, tractors, and compact designs. Ideal for construction sites, outdoor activities, and emergency power backup.

- Noise level: While water-cooled generators generally provide better noise reduction than air-cooled generators, it is still important to evaluate local noise regulations and requirements. For an extremely quiet environment, water-cooled generators equipped with soundproof enclosures and vibration isolation systems can be selected.

- Cost factor: There is more to it than just the initial purchase price. The total cost of ownership includes installation expenses, infrastructure requirements, operating costs (such as fuel and water consumption), and ongoing maintenance expenses. BISON water-cooled generators are known for their low maintenance costs and fuel efficiency, which saves money in the long run.

Application scenarios of water cooled generators

| Application category | Typical applications | Common installations |

|---|---|---|

| Industrial applications |

Small to medium manufacturing Light industrial processes Workshop equipment Assembly lines |

Small factories Processing facilities Workshop facilities Light manufacturing |

| Power plant |

Auxiliary power systems Backup power units Control systems Emergency lighting |

Small power stations Control rooms Auxiliary facilities Monitoring stations |

| Large facilities |

Building systems Critical equipment HVAC support Security systems |

Office buildings Shopping centers Educational facilities Medical clinics |

| Emergency power supply |

Backup power Emergency lighting Critical systems Safety equipment |

Small hospitals Emergency centers Security facilities Data rooms |

| Commercial use |

General power Lighting systems Air conditioning Office equipment |

Retail stores Restaurants Small offices Entertainment venues |

reliable water cooled generator company

BISON is a leading water cooled generator company in China, combining innovation with reliability to provide superior power solutions. As a professional manufacturer, we are proud of our advanced production technology, first-class staff, and strict quality control system.

BISON offers a variety of water cooled generators, and to meet the professional needs of different users, we also provide different engine brands to achieve user customization.

For dealers who want to expand their product portfolio with reliable, efficient, and technologically advanced generator solutions, BISON provides a perfect combination of quality, service, and value. As a generator manufacturer with many years of experience, BISON is committed to providing the most professional and complete services to establish lasting partnerships with dealers and customers around the world.

Contact BISON’s sales team now to explore our comprehensive range of water-cooled generators and experience BISON’s unique advantages in the field of power generation.

Table of Contents

our latest articles