Why is my generator shaking/vibrating?

- BY BISON

Table of Contents

If you’ve ever been around an open diesel or gasoline generator running, you know that it can be loud. While all generators produce some degree of vibration during normal operation—due to their internal combustion engines and moving components—excessive shaking or vibration should never be ignored.

If your generator is shaking or vibrating more than usual, it could be a sign that it needs a thorough inspection to avoid costly repairs down the road. This article will help you understand why your generator is shaking/vibrating and provide practical troubleshooting steps to diagnose specific problems, helping you minimize vibration issues.

Normal vs. abnormal generator vibration

Inside these engines, pistons rapidly move up and down within cylinders, converting fuel into mechanical energy. As the pistons fire in sequence and the crankshaft rotates, these movements create inherent vibrations that transfer throughout the generator’s structure.

When the generator is operating normally, you should hear a slight hum or slight vibration that is consistent, predictable and maintains a steady vibration level throughout the operation.

Abnormal vibration, however, presents differently and warrants attention. You should be concerned if:

- The intensity of vibration suddenly increases.

- The generator develops a new or unusual shaking pattern.

- Rhythmic thumping or impact

- The vibration causes the generator to move or “walk” across its mounting surface.

- The operational noise becomes significantly louder or develops rattling, knocking, or metallic sounds.

- Items placed on or near the generator vibrate excessively or fall off.

While occasional fluctuations may occur during load changes, constant or increasing vibrations usually indicate that something has changed within the generator’s mechanical system. You should have your generator serviced as soon as possible!

Common causes of generator vibration

1. Mechanical issues

- Unbalanced rotating components: When components like flywheels, rotors, or fans become unbalanced due to wear, damage, or improper installation, they create cyclical vibrations as they rotate.

- Misaligned engine parts: If a generator component (such as the engine, rotor, or crankshaft) is not properly aligned, the generator will vibrate regardless of the speed. And the vibrations usually increase under load.

- Loose or worn mounting hardware: Bolts and fasteners that secure engine components or the generator to its base can loosen over time due to normal vibration. Once loose, these components create additional movement and noise.

- Deteriorated anti-vibration mounts: The rubber or spring dampeners designed to absorb vibration can become compressed, hardened, rusted, or broken with age and use. As a result, the generator begins to vibrate due to the reduced holding force and ineffective vibration isolation.

- Worn bearings: As they wear out, they allow excessive movement that manifests as vibration, often accompanied by unusual noises.

2. Engine-related problems

- Fuel system issues: Problems with fuel delivery, quality, or mixture—such as clogged fuel filters, carburetor issues, or injector problems—can lead to uneven combustion and increased vibration.

- Non-uniform/low rpm: Rpm (revolutions per minute) measures how fast the engine runs. If rpm is low or unstable, internal engine parts such as the crankshaft, flywheel, or rotor can vibrate due to improper combustion cycles.

- Incorrect choke position: The choke controls airflow into the carburetor. If it is not correctly set for the weather conditions, it can create an improper air-fuel mixture, leading to vibrations, fluctuations in voltage, overheating, and poor engine performance.

- Ignition timing problems: Improper timing causes the pistons to fire at suboptimal moments, leading to erratic engine operation and noticeable vibration.

- Air intake restrictions: Dirty air filters or obstructed intakes reduce the engine’s oxygen supply, resulting in incomplete combustion and rough engine performance.

- Exhaust blockages: Restrictions in the exhaust system increase back pressure, affecting engine efficiency and causing vibration.

- Cylinder compression problems: Worn piston rings, damaged valves, or cylinder wall scoring can lead to loss of compression, resulting in uneven power delivery and increased vibration.

3. Load-related issues

- Overloading: Connecting too many devices forces the generator to operate beyond its rated capacity, leading to engine strain and vibration.

- Uneven load distribution: Imbalanced electrical loads across the generator’s output create uneven mechanical stress, leading to vibration.

- Sudden load changes: Abrupt increases or decreases in electrical demand can momentarily shock the system, causing temporary spikes in vibration.

4. Environmental factors

- Uneven mounting surface: Mounting the generator on an uneven, soft, or unstable surface without proper support and without using strong stainless steel bolts can cause it to move during normal operation and amplify vibrations.

- External vibrations: Nearby machinery or equipment May generate vibrations and transmit them through the floor or supporting structure, causing instability in the generator.

- Weather conditions: Extreme temperatures can impact engine performance, fuel quality, and component tolerances, potentially increasing vibration during operation.

5. Lack of maintenance

- Oil issues: Engine oil is the only lubricant that ensures the engine’s moving parts run smoothly without excessive friction. Insufficient oil level, oil burnout, oil degradation, or using an inappropriate viscosity will reduce lubrication and increase friction, causing vibration, creaking, noise, and overheating.

- Carbon buildup: Carbon deposits that build up in the combustion chamber can cause rough running and misfires, which can cause the engine to run erratically.

- Corroded electrical connections: Poor electrical connections can cause resistance, voltage fluctuations, and cause erratic generator performance.

- Neglected component replacement: Failure to replace worn parts on a scheduled maintenance schedule can cause friction between parts or minor anomalies that develop into serious vibration problems.

Troubleshooting steps you can take

When your generator vibrates excessively, here are some practical steps you can take to diagnose and potentially resolve the problem:

1. Safety first

- Before performing any troubleshooting or maintenance:

- Completely shut down the generator

- Disconnect all electrical loads and allow the unit to cool (more than 30 minutes)

- Wear personal protective equipment

- Work in a well-ventilated area

- Use appropriate tools and follow the manufacturer’s manual

2. Check the operating surface

- Make sure it is on a solid, level, and stable surface and bolted in place

- Check for surface damage or flexing under load

- Use vibration-dampening pads for portable generators if needed

- Refer to the BISON manufacturer’s placement and mounting recommendations

3. Inspect mounting bolts and hardware

- Check all mounting bolts on the engine, frame, alternator, feet, handles, and control panel.

- Look for elongation, thread damage, or worn connections

- Tighten any loose bolts per the owner’s manual

- Examine anti-vibration mounts

- Locate rubber or spring dampeners between the engine/alternator and frame

- Look for cracks, compression, or deterioration

- Push gently on the engine (with it off) to check the flexibility

- Replace missing or damaged mounts with compatible parts

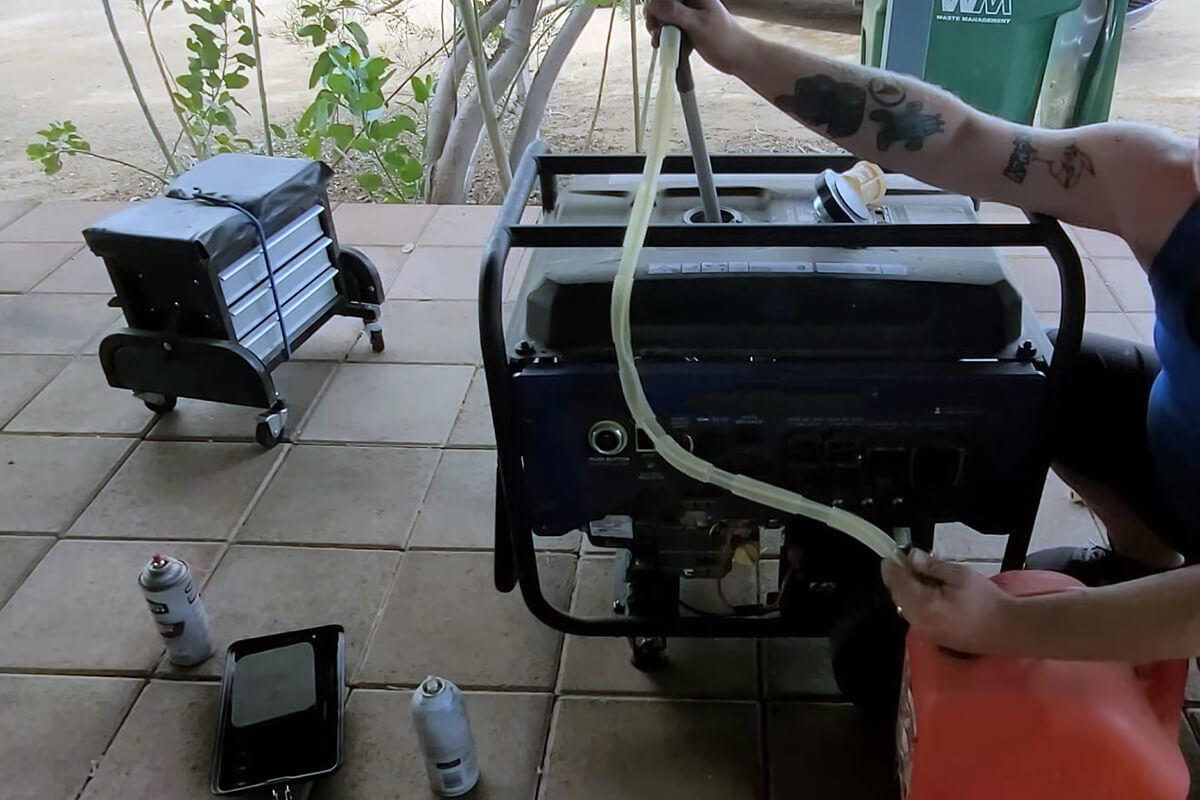

4. Check fuel and fuel system

- Verify engine oil level is correct and oil is clean (not dark, milky, or metallic)

- Use the recommended oil viscosity and change oil every 100–200 hours or 6–12 months.

- Drain fuel that has been stored for several months

- Use clean, high-quality fuel that meets manufacturer specs

- Inspect the fuel system for clogs or delivery issues

- Check the rpm: Use a tachometer or hertz meter and adjust the throttle screw if needed. Overloading beyond the generator’s rated capacity can also cause vibration.

- Choke usage: During cold starts, keep the choke closed; once the engine warms up, move it to the run position for proper fuel-air mixing.

5. Inspect filters

- Remove and inspect the air filter for dirt, debris, or oil

- Clean or replace according to the maintenance schedule

- Check the fuel filter for blockages and replace it if contaminated

6. Check the spark plug condition

- Remove the spark plug and check for fouling, damage, or carbon buildup

- Verify the spark plug gap matches the specifications

- Clean or replace as necessary

- Reinstall and tighten to the correct torque

7. Listen and observe during operation

If vibration persists, observe during operation:

- Listen for unusual sounds like knocking or tapping

- Notice if vibration changes with engine speed or electrical load

- Try to identify whether the vibration originates from the engine or alternator

Conclusion

As we explore in this article, generator vibration can range from normal operating motion to problematic excessive shaking. While all generator systems will experience some degree of vibration, distinguishing between acceptable vibration levels and worrisome levels is critical to proper maintenance and operation. It can also indicate a more serious internal problem with engine components, bearings, or alignment that requires professional attention.

As a professional generator manufacturer, we know that your generator represents safety and continuity at critical moments. The generators provided by BISON are made of strictly screened materials and have undergone multiple links of quality inspection. We have eliminated the vibration/vibration problems caused by product quality to the greatest extent possible to protect you and your customers. Contact BISON now to get a batch of reliable generators!

FAQs

How to properly store your generator?

To balance the load on your generator, divide the electrical demand evenly across its available capacity. Avoid overloading and follow the manufacturer's guidelines for proper load distribution.

Can the size and weight of the generator contribute to vibration?

Yes, the size and weight of a generator can impact its stability. Make sure the generator is properly sized for your load requirements and placed on a solid, level surface that supports its weight.

Can generator vibration damage connected equipment or electronics?

Yes, excessive vibration can harm connected devices or electronics. It's important to resolve vibration issues promptly to protect both the generator and any attached equipment.

contact us

related product categories

Get in touch to speak with our experts!