Why is there oil in generator air filter?

- BY BISON

Table of Contents

A common issue generator owners face is finding oil in the air filter—an indication of possible engine trouble or poor maintenance. Although concerning, it usually stems from underlying issues such as engine wear, overfilling oil, or environmental factors.

An oil-soaked filter restricts airflow, leading to poor engine performance, higher fuel consumption, and potential long-term damage from incomplete combustion and carbon buildup. If your generator is running rough or won’t start, inspect the spark plugs and air filter first. A dark, oil-soaked filter—once white and cotton-like—is a clear sign the issue needs prompt attention.

So, Why is there oil in the generator air filter? BISON will explain it in more detail and tell you a more comprehensive solution in this blog.

Effects of oil soaking in generator air filters

The air filter is essential for protecting the generator’s engine by trapping dust and debris before they enter the combustion chamber. A clean filter allows proper airflow, enabling efficient combustion and helping the engine deliver consistent power while using fuel efficiently.

However, when oil soaks into the air filter, several issues can arise:

Restricted airflow

Excess oil clogs the filter, reducing the amount of clean air entering the engine. This limits combustion efficiency and overall engine performance.

Increased fuel consumption

When airflow is restricted, the engine must work harder to maintain its power output, resulting in higher fuel consumption and reduced fuel efficiency.

Engine overheating and damage

Limited airflow may cause the engine to run lean—an imbalance in the air-fuel mixture—which can result in overheating and damage to pistons, valves, and other internal parts.

Carbon buildup

Poor combustion can lead to carbon deposits forming inside the engine. Over time, this buildup degrades performance and may cause engine knocking or pinging.

Oil is drawn into the engine

If the filter is heavily soaked, oil can be sucked into the combustion chamber, fouling spark plugs, increasing emissions, and potentially damaging the catalytic converter.

Common reasons why oil might appear in a generator’s air filter

1. Overfilled engine oil (too much oil in crankcase)

Over-adding oil usually occurs during an oil change, such as a false dipstick reading, or when checking the oil level while the generator is running or tilted. Excess oil causes increased pressure inside the crankcase when the engine is running. This pressure can push tiny oil droplets, called oil mist, through the engine’s breather system and into the air filter.

What to look for: Oil leaks, white smoke from the exhaust, or a wet air filter.

2. Worn piston rings or cylinder walls

When these parts wear, they can no longer effectively seal the combustion gases. This results in blowby. Hot gases and oil vapor escape from the piston, and crankcase pressure increases. Then, oil vapor is pushed into the intake and deposited on the air filter.

Signs: Increased oil consumption, decreased engine power, or smoking exhaust.

3. Clogged PCV system (positive crankcase ventilation)

The PCV system relieves internal engine pressure. If the valve or breather hose is blocked, pressure builds and forces oil into the intake system.

Symptoms: Rough idle, oil around the PCV valve, or oil-soaked air filter.

4. Running on an uneven surface

Uneven roads can cause problems with the direction and pattern of engine oil flow. If the generator is running on a slope, soft ground, or uneven roads, the oil may overflow the valve cover and flow into the air filter through the breather tube.

5. Using the wrong type or grade of oil

Oil that is too thin (low viscosity) may not stay where it should and is more likely to become mist and be pushed into the air filter. , especially if the engine is hot.

6. Restricted or dirty air filter

A clogged air filter increases vacuum pressure in the intake, which may suck more oil mist from the crankcase ventilation system.

Check for: A dark, sticky filter or reduced engine performance.

7. Engine overheating

When the engine gets too hot (often above 200°F), oil becomes thinner and vaporizes more easily. This vapor can travel through the breather system and accumulate in the air filter. Prolonged overheating boosts internal pressure and increases oil mist, contributing to oil-soaked filters and potential component wear.

Correct maintenance, prevention measures, and solutions for oil in the air filter.

Regular maintenance

Always follow your generator manual and the manufacturer’s recommendations. Look for signs of oil buildup in the air filter housing during scheduled checks. Early detection helps avoid bigger issues.

Proper oil filling

- Use a dipstick: Always check oil levels with the dipstick to ensure it’s within the correct range.

- Add oil slowly: Use a long-neck funnel to make filling easier and more precise.

- Correct overfilling: If the oil level is too high, open the drain plug briefly with a wrench to release excess oil. Then, recheck and top off carefully if needed.

PCV system inspection

- Locate and inspect: Find the PCV valve and hose—typically a small component connected to the valve cover.

- Clean or replace: If clogged or damaged, clean it thoroughly or install a new one.

Keep the generator level during use

- Always operate on a flat surface: Avoid hills, soft ground, or placing blocks under one side.

- Check oil on level ground: An angled dipstick reading can give a false “full” reading and cause overfilling.

Use the correct oil type and grade

Always use the oil grade specified in your generator’s user manual, especially in different temperature conditions.

Consider a compression test

If the problem persists and you suspect internal wear, perform a compression test, which can help identify worn piston rings or cylinder walls that may be causing excessive blowby.

Know when to call a professional

Persistent symptoms mean that specialist intervention is needed, such as persistent oil in the air filter, high oil consumption, visible smoke, or loss of engine power. A qualified technician can inspect deeper engine issues(e.g., compression testing) and perform necessary repairs.

How to clean a generator air filter in 6 easy steps

Step 1: Turn off the generator and let it cool

Turn off the generator and let it sit for at least 30 minutes to prevent burns from hot parts or oil.

Step 2: Disconnect the spark plug

Remove the spark plug to prevent accidental starting during maintenance.

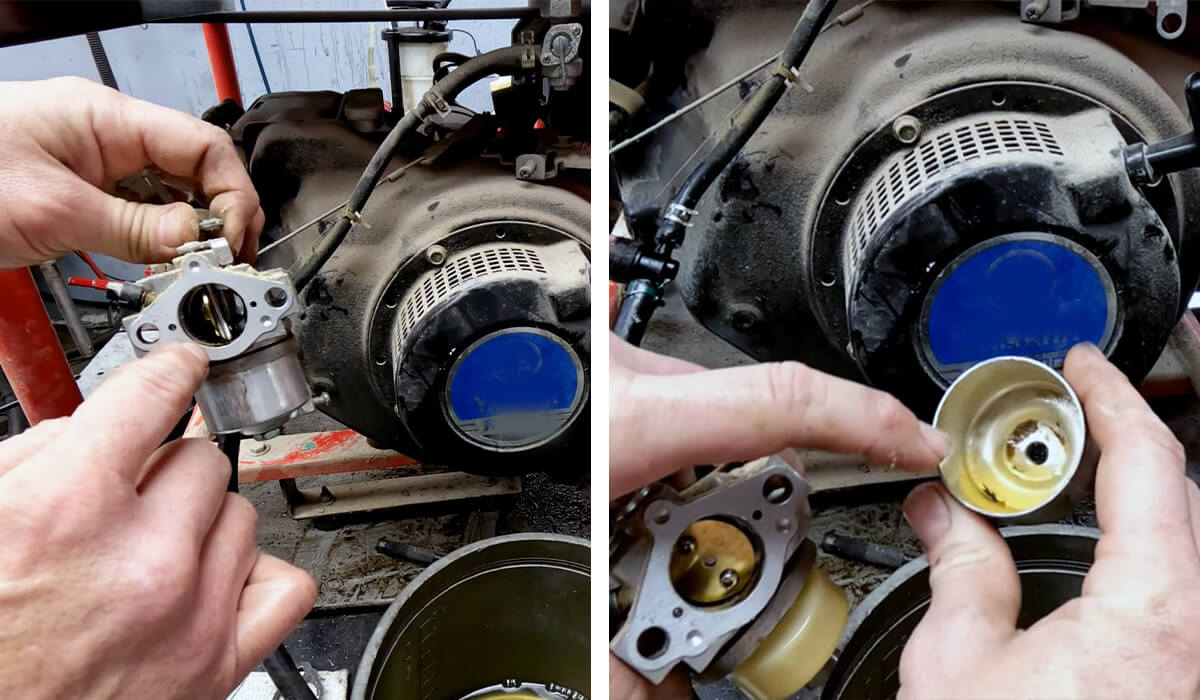

Step 3: Remove and inspect the air filter

Locate the air filter housing and use a screwdriver or wrench (depending on the model) to remove the bolts. Take out the air filter. If the foam is damaged or falling apart, it’s best to replace it.

Step 4: Clean the air filter

Gently tap the air filter or use a soft brush to remove any dirt or debris. Rinse thoroughly with soapy water or light water pressure. This process can be repeated until the air filter is clean and completely dry.

Step 5: Oil the air filter

Apply a small amount of clean engine oil to the side of the foam that faces the engine.

Step 6: Reassemble everything

Place the filter back with the oiled side facing the engine. Reinstall the housing and bolts, connect the spark plugs, and the generator is ready for use.

For more information, please see “How to clean and replace air filter for generator“.

Conclusion

A leaking generator air filter is a serious problem that should not be ignored. It is often indicative of excessive crankcase oil, an engine oil leak, or using the generator on uneven roads. To protect your generator and ensure reliable performance, be sure to refer to the maintenance guidelines above to start a maintenance plan and best practices.

As a professional generator manufacturer in China, we emphasize the importance of regular and proactive maintenance, and we also understand the tediousness and complexity of maintenance procedures. In order to reduce the probability of generator failure, BISON is more rigorous in material selection and structural design. If you are a dealer looking for a cost-effective generator, contact BISON now to get a generator with less downtime.

FAQs

How often should I clean my generator's air filter?

The recommended interval is every 50 hours of operation or at least once a year, whichever comes first. However, if you use your generator frequently or operate it in dusty environments, you may need to clean the filter once or twice a month and replace it once or twice a year, depending on its condition.

Can I reuse the air filter after cleaning?

Yes, as long as the air filter is not damaged or excessively worn, it can be reused. Ensure it is completely dry before reinstalling. If the foam is torn, brittle, or no longer fits properly, replacement is recommended.

contact us

related product categories

Get in touch to speak with our experts!