How does the diesel generator cooling system work?

- BY BISON

Table of Contents

A diesel generator’s cooling system is vital for its correct functioning and extended lifespan. By eliminating excessive heat generated during engine operation, the system prevents potential damage. It operates by circulating coolant or water within the engine block and radiator, effectively absorbing and releasing heat. The now-cooled coolant re-enters the engine for the cycle to continue. Additionally, the cooling system helps regulate the engine’s temperature, promoting optimal performance and efficiency. Proper maintenance of this critical component ensures the generator’s dependability and longevity.

Diesel Engine Cooling System: Working Principle

The cooling system of a diesel engine is an essential component engineered to inhibit engine overheating and sustain the ideal operating temperature. Its main purpose is to disperse the heat produced by the combustion process inside the engine. This safeguards the engine’s components against damage caused by extreme heat and guarantees effective performance. The subsequent sections explain the operational principle of a diesel engine cooling system.

Main Components

The cooling system in a diesel engine consists of several key components, including:

- Radiator

- Water pump

- Thermostat

- Coolant

- Cooling fan

- Hoses and pipes

- Temperature sensors and gauges

Types of Cooling Systems

There are two primary types of cooling systems in diesel engines:

- Liquid Cooling System: The predominant cooling system type, which involves a coolant (typically a blend of water and antifreeze) flowing through the engine and radiator to eliminate heat.

- Air Cooling System: This cooling system variety employs air to lower the engine’s temperature. Cooling fins on the engine’s exterior augment the surface area for heat dissipation, and a fan directs air over the fins, extracting heat from the engine.

In conclusion, the cooling system of a diesel engine is crucial for preserving the ideal working temperature and avoiding excessive heat. The primary elements of the system cooperate to circulate the coolant, disperse heat, control temperature, and oversee the engine’s performance, resulting in effective and dependable functioning.

Diesel Generator Cooling System Advantages

The diesel generator cooling system is a crucial part of a diesel generator, offering numerous essential advantages:

Temperature Regulation: The cooling system is engineered to maintain the engine at its ideal operating temperature, avoiding overheating and subsequent engine damage.

Dependability: By preserving the appropriate temperature, the cooling system guarantees that the generator operates dependably and consistently.

Durability: The cooling system contributes to the generator’s extended lifespan by preventing overheating and engine damage.

Efficiency: A well-kept cooling system enhances the generator’s efficiency, enabling it to function at its maximum capacity.

Safety: A properly working cooling system helps avert fires and explosions resulting from overheating, ensuring the generator and its surroundings remain secure.

Engine Protection: By allowing the engine to function at a consistent temperature and optimal capacity, the cooling system effectively extends its lifespan.

Cost Effective: Ensuring regular maintenance of your cooling system saves money as it reduces the need for repairs and replacements due to overheating.

In conclusion, the cooling system of a diesel generator is a crucial element that greatly impacts the generator’s dependability and efficiency.

Diesel Generator Cooling System Maintenance

To ensure the proper functioning of the diesel generator cooling system and prolong the generator’s lifespan, it is essential to perform regular maintenance. Here are some key maintenance steps to follow:

Inspect coolant level: Routinely check the coolant level to confirm that it’s at the appropriate level and free from contamination. A low coolant level might indicate a leak in the system.

Examine hoses and pipes: Inspect hoses and pipes for any signs of wear or leaks. Promptly repair any detected cracks or leaks.

Evaluate Radiator and Oil Cooler: Check the radiator and oil cooler for debris and blockages that could block coolant flow and reduce cooling system efficiency.

Assess the water pump: Inspect the water pump for any leakage and search for indications of wear or deterioration.

Main components of diesel generator cooling system

The primary elements of a diesel generator cooling system consist of:

Water pump: A belt connected to the engine crankshaft drives the water pump, which circulates the coolant throughout the engine.

Oil coolers: In addition to the radiator, certain diesel generators are equipped with oil coolers that function similarly and help to cool the engine oil.

Radiator fan: The radiator fan helps to dissipate heat from the radiator.

Hoses and pipes: The cooling system’s various components receive the coolant through hoses and pipes.

Expansion tank: As the coolant heats up and expands, the expansion tank provides space for it.

Pressure cap: The cooling system’s pressure is maintained by the pressure cap.

Temperature gauge or sensor: The coolant’s temperature is monitored by this component, which transmits signals to the generator control system.

Additional Points to Consider:

Coolant System Cleanse: Regularly cleansing the coolant system aids in eliminating any accumulation of debris or corrosion, potentially affecting the system’s effectiveness. This procedure consists of emptying the used coolant, rinsing the system using a cleaning agent, and replenishing it with new coolant.

Cooling System Cleanse: Carrying out a regular flush of the cooling system aids in eliminating any accumulated debris or corrosion, consequently enhancing the system’s effectiveness. This procedure entails draining the used coolant, purging the system using a cleansing agent, and replenishing it with new coolant.

Thermostat Upkeep: The thermostat is responsible for controlling the circulation of coolant within the engine, maintaining the ideal temperature. Periodically examine the thermostat for correct operation and substitute it if needed.

Belt Tension: Ensure that the belts driving the water pump and radiator fan are correctly tensioned and in good condition. Loose or worn belts can lead to reduced cooling efficiency and potential engine overheating.

Optimization of Airflow: Maintain a clean and unobstructed space around the generator for effective heat dispersion. Sufficient airflow is crucial for both air-cooled and liquid-cooled systems.

Monitoring System: Implementing a monitoring system can help detect issues with the cooling system before they become critical. Regularly reviewing temperature readings and other system data can identify potential problems early, allowing for timely maintenance and repairs.

Training and Education: Ensure that personnel responsible for maintaining the diesel generator are adequately trained and knowledgeable about the cooling system’s components and maintenance requirements. This will help ensure proper care and prolong the life of the generator.

In summary, a well-maintained diesel generator cooling system is essential for efficient and reliable operation. By considering these additional points and regularly inspecting and servicing the system, you can ensure optimal performance and extend the lifespan of your diesel generator.

Conclusion

Overall, the diesel generator cooling system includes a combination of mechanical and electronic components that work together to remove heat from the engine and maintain a safe operating temperature.If you want to buy other generator parts, welcome to BISON to check.

diesel generator cooling system

How does a diesel generator cooling system work?

A diesel generator cooling system works by circulating a coolant, typically a mixture of water and antifreeze, through the engine to transfer heat away from it and into the atmosphere. The coolant is circulated through the engine by a diesel generator water pump and passes through radiators or heat exchangers to dissipate the heat. The cooling system includes several key components such as diesel generator radiator, diesel generator thermostat, and diesel generator oil cooler.

What are the components of a diesel generator cooling system?

The main components of a diesel generator cooling system include: water pump, radiator, thermostat, coolant, oil coolers, radiator fan, hoses, pipes, expansion tank, pressure cap, and temperature gauge or sensor.

What are the benefits of a properly functioning diesel generator cooling system?

A properly functioning diesel generator cooling system provides several key benefits: temperature control, reliability, longevity, efficiency, safety, engine protection and cost-effectiveness.

How to maintain diesel generator cooling system?

Proper maintenance is crucial to ensure that the diesel generator cooling system functions properly and extends the life of the generator. The following are some key maintenance steps that should be performed regularly: check coolant level, check hoses and pipes, check the radiator and oil coolers, check the water pump, check the thermostat, check the radiator fan, check for leaks and blockages and check the coolant for contamination.

What is the importance of diesel generator cooling system?

The diesel generator cooling system is an essential component of a diesel generator that plays a critical role in ensuring the safe and reliable operation of the generator. The cooling system is responsible for removing the heat generated by the combustion process in the engine and keeping the engine at its optimal operating temperature.

contact us

Please complete our contact form and we will soon get back to you with expert advice.

business

Get in touch to speak with our experts!

How a generator transfer switch works: comprehensive guide

Next, BISON will explore generator transfer switches in this article. Read on to learn how they work, why they are vital, and more.

How many dB is a quiet generator?

Want to know how many dB is a quiet generator? Read this blog post, you’ll only know the answer to this question but also more information on quiet generators.

Cylinder Pulling In Diesel Generator

BISON will help you understand the key steps of the diesel generator set wear process and maintenance process. Get the best performance and reliability.

Diesel generator running in rainy weather

Want to know whether you can run a generator in rainy weather or not? Or how to use a generator in rainy weather? Then this blog post is for you. Let’s get started!

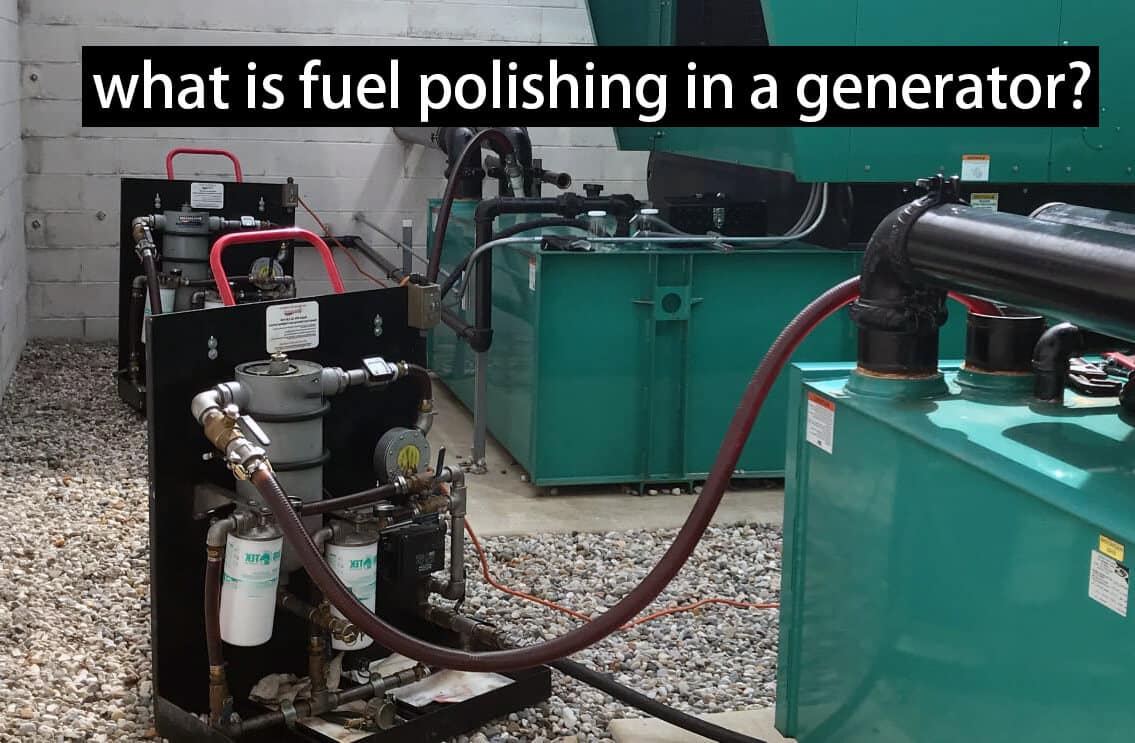

what is fuel polishing in a generator?

Fuel polishing is the very fine filtration of diesel fuel to remove impurities like dirt and water, you’ll find everything you need to know. Start with BISON.

Can a regular generator handle welding?

It is more important to have a clear understanding of the considerations involved when using regular generators for welding, along with potential risks, etc.